地址:浙江省永嘉县东瓯街道东瓯工业园区

销售热线:0577-67980810

联 系 人:浙江扬子江泵业有限公司

传 真: 0577-67986930

邮政编码:325105

销售热线:0577-67980810

联 系 人:浙江扬子江泵业有限公司

传 真: 0577-67986930

邮政编码:325105

单螺杆泵选型

点击次数:2986 发布时间:2017/8/4 20:23:37

一、单螺杆泵性能参数(试验介质20℃清水)

|

标准

型号 Standard model |

每100转理论流量

Theoretical flow(L)/100 revolutions |

允许工作压力(MPa)

Allowable max particulate size (mm) |

允许大颗粒粒径(mm)

Allowable max particulate size(mm) |

转速流量近似成正比关系

Rotation flow is approximate to proportion |

泵合理流量范围(m3/h)

Rational flow range of pump(m3/h) |

佳工作

转速 Optimum working rotation velocity(r/min) |

配套电机

功率(KW) Power of the matching motor(kw) |

吸入法兰

Pump-in flange |

排出法兰

Pump-out flange |

配套代号

与方式 Matching code and mode |

||||

|

泵400r/min 时流量(M3/h)

Flow(m3/h)when the pump is 400r/min |

孔径

(mm) Orifice size (mm) |

通径

(mm) Though oath (mm) |

孔径

(mm) Orifice size (mm) |

通径

(mm) through path (mm) |

可选方式(代号)

Options(code) |

有以下多种配套方式

A suite of configuration available as shown as below |

||||||||

|

G15-1

|

1.63

|

0-0.6

|

3

|

0.3

|

0.3-0.8

|

400-1000

|

0.55-0.75

|

125

|

50

|

110

|

40

|

1.2.3.4.

5. |

|

|

|

G15-2

|

1.63

|

0-12

|

3

|

0.3

|

0.3-0.8

|

400-1000

|

0.75-1.1

|

125

|

50

|

110

|

40

|

|||

|

G15-3

|

1.63

|

0-18

|

3

|

0.3

|

0.3-0.8

|

400-1000

|

1.1-1.5

|

125

|

50

|

110

|

40

|

|||

|

G15-4

|

1.63

|

0-2.4

|

3

|

0.3

|

0.3-0.8

|

400-1000

|

1.5-2.2

|

125

|

50

|

110

|

40

|

|||

|

G25-1

|

6.27

|

0-0.6

|

5

|

1.2

|

1-3.4

|

400-900

|

1.1-1.5

|

125

|

50

|

110

|

40

|

|||

|

G25-2

|

6.27

|

0-1.2

|

5

|

1.2

|

1-3.4

|

400-900

|

1.5-2.2

|

125

|

50

|

110

|

40

|

|||

|

G25-1A

|

12.65

|

0-0.6

|

5

|

2.4

|

2-5.5

|

400-900

|

1.5-2.2

|

125

|

50

|

110

|

40

|

|||

|

G35-1

|

13.11

|

0-0.6

|

6

|

2.7

|

4-6

|

400-900

|

2.2-3

|

145

|

65

|

145

|

65

|

|||

|

G35-2

|

13.11

|

0-1.2

|

6

|

2.7

|

4-6

|

400-900

|

3-4

|

145

|

65

|

145

|

65

|

|||

|

G40-1

|

24.91

|

0-0.6

|

8

|

5.0

|

6-8

|

400-800

|

2.2-3

|

145

|

65

|

145

|

65

|

|||

|

G40-2

|

24.90

|

0-1.2

|

8

|

5.0

|

6-8

|

300-600

|

4-4.5

|

160

|

80

|

160

|

80

|

|||

|

G40-3

|

24.90

|

0-1.8

|

8

|

4.8

|

6-8

|

300-500

|

5.5-7.5

|

160

|

80

|

160

|

80

|

|||

|

G40-4

|

24.90

|

0-2.4

|

8

|

4.5

|

6-8

|

300-500

|

7.5-11

|

180

|

100

|

145

|

65

|

|||

|

G50-1

|

49.62

|

0-0.6

|

10

|

10.5

|

8-13

|

300-500

|

4-5.5

|

160

|

80

|

160

|

80

|

2.3.4.5

|

||

|

G50-2

|

49.62

|

0-1.2

|

10

|

10.5

|

8-13

|

300-500

|

7.5-11

|

170

|

100

|

160

|

80

|

|||

|

G50-3

|

49.62

|

0-1.8

|

10

|

10.0

|

8-13

|

300-500

|

11-15

|

200

|

125

|

180

|

100

|

|||

|

G50-4

|

49.62

|

0-2.4

|

10

|

10.0

|

8-13

|

250-400

|

15-18.5

|

200

|

125

|

180

|

100

|

|||

|

G60-1

|

103.91

|

0-0.6

|

11

|

20.0

|

13-20

|

300-450

|

7.5-11

|

170

|

100

|

160

|

80

|

2.3.5.

6.7 |

||

|

G60-2

|

103.91

|

0-1.2

|

11

|

20.0

|

13-20

|

300-450

|

11-15

|

170

|

100

|

160

|

80

|

|||

|

G60-3

|

103.91

|

0-1.8

|

11

|

20.0

|

13-20

|

300-400

|

15-18.5

|

200

|

125

|

180

|

100

|

|||

|

G60-4

|

103.91

|

0-2.4

|

11

|

19.0

|

13-20

|

300-400

|

18.5-22

|

200

|

125

|

180

|

100

|

|||

|

G70-1

|

105.10

|

0-0.6

|

13

|

24.0

|

20-24

|

300-450

|

11-15

|

200

|

125

|

180

|

100

|

|||

|

G70-2

|

105.10

|

0-1.2

|

13

|

24.0

|

20-24

|

250-400

|

15-18.5

|

200

|

125

|

180

|

100

|

|||

|

G70-A1

|

105.12

|

0-0.6

|

13

|

30.0

|

24-30

|

300-450

|

11-15

|

210

|

125

|

210

|

125

|

|||

|

G85-1

|

221.60

|

0-0.6

|

15

|

43.0

|

30-35

|

250-350

|

15-18.5

|

210

|

125

|

210

|

125

|

|||

|

G85-2

|

177.60

|

0-1.2

|

15

|

35.0

|

28-53

|

250-350

|

18.5-22

|

210

|

125

|

210

|

125

|

|||

|

G85-3

|

201.60

|

0-1.8

|

15

|

40.0

|

30-35

|

250-350

|

30-37

|

280

|

200

|

295

|

200

|

|||

|

G85-4

|

198.50

|

0-2.4

|

15

|

39.0

|

25-32

|

200-300

|

37-45

|

280

|

200

|

295

|

200

|

2.3.5.

6.7.8 |

||

|

G105-1

|

400.43

|

0-0.6

|

18

|

74.0

|

35-50

|

250-350

|

22-30

|

280

|

200

|

295

|

200

|

|||

|

G105-2

|

400.43

|

0-1.2

|

18

|

74.0

|

35-50

|

250-350

|

37-45

|

280

|

200

|

295

|

200

|

2.3.5.

7.8.9 |

||

|

G110-1

|

532.40

|

0-0.6

|

24

|

105.0

|

50-80

|

200-300

|

22-30

|

280

|

200

|

295

|

200

|

|||

|

G110-2

|

532.40

|

0-1.2

|

24

|

105.0

|

50-80

|

200-300

|

30-37

|

280

|

200

|

295

|

200

|

|||

|

G110-3

|

532.40

|

0-1.8

|

24

|

100.0

|

50-80

|

200-300

|

37-45

|

280

|

200

|

295

|

200

|

|||

|

G110-4

|

530.40

|

0-2.4

|

24

|

98.0

|

45-76

|

180-280

|

45-75

|

280

|

200

|

295

|

200

|

|||

|

G120-1

|

764.64

|

0-0.6

|

30

|

146.0

|

80-110

|

200-300

|

30-37

|

280

|

200

|

295

|

200

|

|||

|

G120-2

|

764.64

|

0-1.2

|

30

|

146.0

|

80-110

|

200-300

|

37-45

|

280

|

200

|

295

|

200

|

|||

|

G135-1

|

835.58

|

0-0.6

|

35

|

160.0

|

110-130

|

150-280

|

37-45

|

280

|

200

|

295

|

200

|

|||

|

G135-2

|

835.58

|

0-1.2

|

35

|

160.0

|

110-130

|

150-280

|

55-75

|

280

|

200

|

295

|

200

|

|||

二、根据泵输送介质的理化性能选择泵的材料组合

|

天然橡胶

NR |

丁晴橡胶

NBR |

食品橡胶

FOOD-ORTENTED RUBBER |

乙丙橡胶

EPDM |

氟橡胶

FPM |

|

水(含污水)

Water (includng waste water) |

◎

|

◎

|

●

|

◎

|

●

|

|

动、植物油

Animal oil and vegetable oil |

×

|

◎

|

●

|

×

|

◎

|

|

矿物油

Mineral oil |

×

|

●

|

●

|

×

|

◎

|

|

氨水

Ammonia water |

×

|

●

|

●

|

×

|

×

|

|

脂肪族浓剂

Fatty solvernts |

×

|

×

|

×

|

×

|

●

|

|

芳香族浓剂

Aromatic solvents |

×

|

×

|

×

|

×

|

●

|

|

浓碱

Thick alkaline |

●

|

●

|

●

|

●

|

●

|

|

浓硝酸

thick nitric acid |

×

|

×

|

×

|

×

|

▲

|

|

冰醋酸

glacial acetic acid |

×

|

●

|

●

|

×

|

●

|

|

稀硫酸

thin sulfuric acid |

×

|

×

|

×

|

●

|

●

|

|

浓硫酸

thick sulfuric acid |

×

|

×

|

×

|

▲

|

●

|

|

稀盐酸

thin hydrochioric acid |

●

|

●

|

●

|

●

|

●

|

|

浓盐酸

thick hydrochioric acid |

×

|

×

|

×

|

●

|

●

|

|

热水

Hot water |

×

|

▲

|

▲

|

●

|

×

|

|

汽油

Gasoline |

×

|

●

|

●

|

×

|

●

|

|

煤油

Kerosene |

×

|

●

|

●

|

×

|

◎

|

|

柴油

Diesel oil |

×

|

●

|

●

|

×

|

●

|

|

氯化烃

Chiorated hydrocarbon |

×

|

×

|

×

|

×

|

▲

|

|

含酮类物料

Ketone containing materials |

×

|

×

|

×

|

×

|

▲

|

|

含醇类物料

Alcohol containing materials |

●

|

●

|

●

|

●

|

●

|

|

含脂类物料

Fat containing materials |

×

|

×

|

×

|

●

|

×

|

|

含醚类物料

Easter containing materials |

×

|

×

|

×

|

●

|

×

|

|

泥浆

Slurry |

●

|

●

|

▲

|

●

|

▲

|

|

耐高温度

Max.temperrature resistance |

70℃

|

90℃

|

90℃

|

180℃

|

130℃

|

|

耐磨性 Wear resistance

|

◎

|

●

|

●

|

◎

|

◎

|

|

耐老化

Aging resistance |

●

|

●

|

●

|

◎

|

◎

|

|

耐臭氧

Ozene resistance |

×

|

×

|

×

|

◎

|

◎

|

|

耐辐射

Radiation resistance |

▲

|

▲

|

▲

|

▲

|

×

|

|

耐燃性

Fire reasistance |

×

|

●

|

●

|

◎

|

×

|

|

抗蒸汽

Steam resistance |

●

|

●

|

●

|

◎

|

◎

|

NOte:a.the food-oriented rubber does not contain assitives detrimental to human health

b、◎优 ●良 ▲一般 ×不行

|

转子、过流部件材质

Aterials for rotor and overcurrent parts |

性能用途

Performance and applications |

|

45 HT200

|

防腐能力差,适用一般介质

With poor corrosion resistance, it is suitable for ordinary media. |

|

1Cr18Ni9Ti ZG1Cr18Ni9Ti

|

耐一般腐钟介质

resist ordinary corrosive media |

|

1Cr8Ni12Mo2Ti ZG1Cr18Ni12M02Ti

|

耐酸碱

resist acids and alkaline |

三、如果介质中含有颗粒状固体或纤维物时,应开始从下表中选择适用的小规格的泵。

按输送介质中含有大固体颗粒直径和纤维长度选泵。

泵规格:

A、G型泵(单位:mm)

A、G type pumps

|

泵规格

Pumps specification |

G15

|

G25

|

G35

|

G40

|

G50

|

G60

|

G70

|

G85

|

G110

|

G120

|

G135

|

|

允许大颗粒直径 |

3

|

5

|

6

|

8

|

10

|

12

|

13

|

15

|

24

|

30

|

35

|

|

允许大纤维长度 |

40

|

60

|

80

|

100

|

120

|

150

|

160

|

200

|

280

|

300

|

520

|

B、TYG型泵(单位:mm)

B、TYG type pumps

|

泵规格

Pumps Specification |

TYG2

|

TYG3

|

TYG4

|

TYG5

|

TYG6

|

TYG8

|

TYG10

|

TYG12

|

TYG14

|

|

允许大颗粒直径 |

3

|

4

|

6

|

8

|

10

|

13

|

17

|

20

|

24

|

|

允许大纤维长度 |

25

|

37

|

50

|

63

|

75

|

100

|

125

|

150

|

175

|

介质中固体的含量一般不超过40%,如固体为粉末微粒时含量高可达60%或更高,如水煤液等。

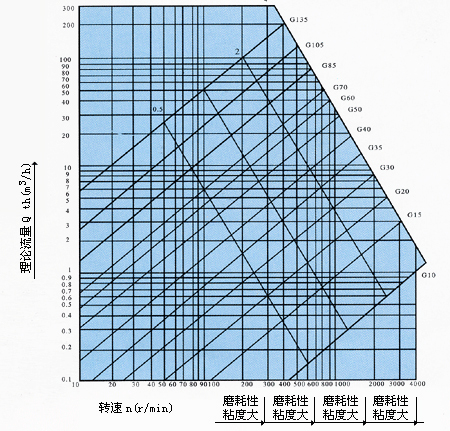

四、按泵输送不同的介质时的转速范围

五、按介质含有磨蚀性物料情况,泵所允许的高运行转速。

A、G型泵

|

泵规格 |

|

无磨蚀

No wear |

轻磨蚀

Light wea |

中等磨蚀

Moderrate wear |

严重磨蚀

Serious wear |

|

G15

|

nmax(r/min)

|

2570

|

1290

|

720

|

385

|

|

Qmax(m3/h)

|

2.15

|

1.08

|

0.6

|

0.32

|

|

|

G25

|

nmax(r/min)

|

1575

|

780

|

550

|

275

|

|

Qmax(m3/h)

|

5.46

|

2.7

|

1.91

|

0.95

|

|

|

G35

|

nmax(r/min)

|

1250

|

720

|

520

|

265

|

|

Qmax(m3/h)

|

8.77

|

5.05

|

3.65

|

1.86

|

|

|

G40

|

nmax(r/min)

|

1035

|

685

|

490

|

255

|

|

Qmax(m3/h)

|

15.41

|

10.2

|

7.29

|

3.8

|

|

|

G50

|

nmax(r/min)

|

880

|

610

|

440

|

245

|

|

Qmax(m3/h)

|

24.68

|

17.11

|

12.34

|

6.87

|

|

|

G60

|

nmax(r/min)

|

755

|

555

|

385

|

230

|

|

Qmax(m3/h)

|

38.23

|

28.11

|

19.5

|

11.65

|

|

|

G70

|

nmax(r/min)

|

725

|

550

|

380

|

220

|

|

Qmax(m3/h)

|

42.87

|

32.53

|

22.47

|

13.01

|

|

|

G85

|

nmax(r/min)

|

635

|

530

|

355

|

215

|

|

Qmax(m3/h)

|

71.75

|

59.89

|

40.11

|

24.29

|

|

|

G110

|

nmax(r/min)

|

500

|

460

|

310

|

180

|

|

Qmax(m3/h)

|

146.93

|

135.18

|

91.1

|

52.9

|

|

|

G120

|

nmax(r/min)

|

450

|

395

|

260

|

160

|

|

Qmax(m3/h)

|

195.34

|

171.47

|

112.86

|

69.46

|

|

|

G135

|

nmax(r/min)

|

435

|

380

|

250

|

150

|

|

Qmax(m3/h)

|

218.09

|

190.52

|

125.34

|

75.2

|

TYG型转定子:

B、TYG型泵

|

泵规格 |

|

无磨蚀

NO wear |

轻磨蚀

Light wear |

中等磨蚀

Moderate wear |

严重磨蚀

Serious wear |

|

TYG2

|

nmax(r/min)

|

3000

|

1600

|

890

|

475

|

|

Qmax(m3/h)

|

3.66

|

1.95

|

1.09

|

0.58

|

|

|

TYG3

|

nmax(r/min)

|

2110

|

1060

|

740

|

370

|

|

Qmax(m3/h)

|

8.82

|

4.43

|

3.09

|

1.55

|

|

|

TYG4

|

nmax(r/min)

|

1580

|

950

|

665

|

355

|

|

Qmax(m3/h)

|

15.77

|

9.48

|

6.64

|

3.54

|

|

|

TYG5

|

nmax(r/min)

|

1270

|

890

|

635

|

350

|

|

Qmax(m3/h)

|

24.87

|

17.43

|

12.43

|

6.85

|

|

|

TYG6

|

nmax(r/min)

|

1190

|

830

|

595

|

330

|

|

Qmax(m3/h)

|

40.5

|

28.25

|

20.25

|

11.23

|

|

|

TYG8

|

nmax(r/min)

|

935

|

695

|

485

|

275

|

|

Qmax(m3/h)

|

75.32

|

55.99

|

39.07

|

22.15

|

|

|

TYG10

|

nmax(r/min)

|

780

|

610

|

415

|

245

|

|

Qmax(m3/h)

|

122.62

|

95.89

|

65.24

|

38.51

|

|

|

TYG12

|

nmax(r/min)

|

680

|

595

|

390

|

240

|

|

Qmax(m3/h)

|

185.14

|

162

|

106.18

|

65.34

|

|

|

TYG14

|

nmax(r/min)

|

600

|

540

|

340

|

215

|

|

Qmax(m3/h)

|

259.2

|

233.28

|

146.88

|

92.88

|

2、各类含磨蚀性物料介质举例:

A、无磨蚀介质:淡水、油、浆汁、甘油、血液、肥皂水等;

B、轻磨蚀介质:软质泥浆,含水95%以上的污泥,如活性污泥水,精糖废液,农畜屎尿,工业废等;

C、中等磨蚀介质:含有固体物料的泥浆,含水85%以上的泥浆,如涂料,糖蜜,研削液,石膏泥浆等;

D、严重磨蚀介质:水煤浆,含有磨蚀性物质的浆液,含水率50%以上的污泥,如研磨液,温泉泥,PVC浆料

,粘土,脱水占结剂等。

D、输送介质的粘度也是选泵需要的一个因素,泵的运行转速随着介质的粘度而降低,若粘度达到150000

mpa以上时,一般结构的泵无法吸入,则必须增设喂料器等特殊设计。

六 按泵输送介质粘度的合适转速(粘度单位:mpa.s)

A、G型

|

泵规格 |

|

1~1500

|

1500~3000

|

3000~10000

|

10000~25000

|

25000~50000

|

50000~100000

|

100000~150000

|

150000以上

|

|

G15

|

nmax(r/min)

|

1685

|

1265

|

560

|

420

|

280

|

60

|

30

|

|

|

Qmax(m3/h)

|

1.41

|

1.06

|

0.47

|

0.35

|

0.23

|

0.05

|

0.025

|

|

|

|

G25

|

nmax(r/min)

|

1110

|

870

|

380

|

280

|

200

|

50

|

25

|

|

|

Qmax(m3/h)

|

3.85

|

3.01

|

1.32

|

0.97

|

0.69

|

0.17

|

0.087

|

|

|

|

G35

|

nmax(r/min)

|

1030

|

845

|

350

|

260

|

185

|

50

|

25

|

|

|

Qmax(m3/h)

|

7.23

|

5.93

|

2.46

|

1.82

|

1.3

|

0.35

|

0.175

|

|

|

|

G40

|

nmax(r/min)

|

900

|

700

|

325

|

250

|

175

|

50

|

25

|

|

|

Qmax(m3/h)

|

12.56

|

9.77

|

4.54

|

3.49

|

2.44

|

0.698

|

0.349

|

|

|

|

G50

|

nmax(r/min)

|

745

|

620

|

300

|

225

|

150

|

50

|

25

|

|

|

Qmax(m3/h)

|

20.89

|

17.39

|

8.41

|

6.31

|

4.21

|

1.4

|

0.7

|

|

|

|

G60

|

nmax(r/min)

|

660

|

565

|

300

|

225

|

150

|

50

|

25

|

|

|

Qmax(m3/h)

|

33.42

|

28.61

|

15.19

|

11.39

|

7.6

|

2.53

|

1.266

|

|

|

|

G70

|

nmax(r/min)

|

635

|

540

|

300

|

225

|

150

|

50

|

25

|

|

|

Qmax(m3/h)

|

37.55

|

29.57

|

17.74

|

13.31

|

8.87

|

2.96

|

1.48

|

|

|

|

G85

|

nmax(r/min)

|

575

|

500

|

300

|

225

|

150

|

50

|

25

|

|

|

Qmax(m3/h)

|

64.97

|

56.5

|

33.9

|

25.42

|

16.95

|

5.65

|

2.82

|

|

|

|

G110

|

nmax(r/min)

|

520

|

450

|

300

|

225

|

150

|

50

|

25

|

|

|

Qmax(m3/h)

|

152.81

|

132.24

|

88.16

|

66.12

|

44.08

|

14.69

|

7.35

|

|

|

|

G120

|

nmax(r/min)

|

450

|

400

|

300

|

225

|

150

|

50

|

25

|

|

|

Qmax(m3/h)

|

195.34

|

173.64

|

130.23

|

97.67

|

65.11

|

21.7

|

10.85

|

|

|

|

G135

|

nmax(r/min)

|

410

|

365

|

300

|

225

|

150

|

50

|

25

|

|

|

Qmax(m3/h)

|

203.53

|

181.19

|

148.93

|

111.69

|

74.46

|

24.82

|

12.41

|

|

B、TYG型泵

|

泵规格 |

|

1~1500

|

1500~3000

|

3000~10000

|

10000~25000

|

25000~50000

|

50000~100000

|

100000~150000

|

150000以上

|

|

TYG2

|

nmax(r/min)

|

1800

|

1350

|

600

|

450

|

300

|

60

|

30

|

|

|

Qmax(m3/h)

|

2.2

|

1.65

|

0.73

|

0.55

|

0.366

|

0.073

|

0.037

|

|

|

|

TYG3

|

nmax(r/min)

|

1250

|

980

|

420

|

310

|

220

|

50

|

25

|

|

|

Qmax(m3/h)

|

5.23

|

4.1

|

1.76

|

1.3

|

0.92

|

0.21

|

0.1

|

|

|

|

TYG4

|

nmax(r/min)

|

1100

|

900

|

375

|

275

|

200

|

50

|

25

|

|

|

Qmax(m3/h)

|

10.98

|

8.89

|

3.74

|

2.75

|

2

|

0.5

|

0.25

|

|

|

|

TYG5

|

nmax(r/min)

|

960

|

745

|

345

|

265

|

185

|

50

|

25

|

|

|

Qmax(m3/h)

|

18.8

|

14.59

|

6.76

|

5.19

|

3.62

|

0.98

|

0.49

|

|

|

|

TYG6

|

nmax(r/min)

|

830

|

690

|

330

|

250

|

165

|

50

|

25

|

|

|

Qmax(m3/h)

|

28.28

|

23.48

|

11.23

|

8.51

|

5.62

|

1.7

|

0.85

|

|

|

|

TYG8

|

nmax(r/min)

|

675

|

575

|

310

|

240

|

160

|

50

|

25

|

|

|

Qmax(m3/h)

|

54.37

|

46.32

|

24.97

|

19.33

|

12.89

|

4.03

|

2.01

|

|

|

|

TYG10

|

nmax(r/min)

|

610

|

530

|

300

|

225

|

150

|

50

|

25

|

|

|

Qmax(m3/h)

|

95.89

|

83.32

|

47.16

|

35.37

|

23.58

|

7.86

|

3.93

|

|

|

|

TYG12

|

nmax(r/min)

|

525

|

450

|

300

|

225

|

150

|

50

|

25

|

|

|

Qmax(m3/h)

|

142.94

|

122.52

|

81.68

|

61.26

|

40.84

|

13.61

|

6.81

|

|

|

|

TYG14

|

nmax(r/min)

|

495

|

430

|

300

|

225

|

150

|

50

|

25

|

|

|

Qmax(m3/h)

|

213.84

|

185.76

|

129.6

|

97.2

|

64.8

|

21.6

|

10.8

|

|

2、表列流量Qmax系泵压p=0时,相应转nmax的理论值。

3、粘度超过150000mpa.s的介质,泵需要特殊设计。

根据以上表格、选定适合的泵,择其大规格者,再按输送压力要求确定泵的级数请参看下表。

七、泵输送不同介质时每级允许的增压

|

泵规格

pump sepcification |

介质含磨蚀物情况

Media with abrasives |

|||

|

无磨蚀

NO wear |

轻磨蚀

Low wear |

中等磨蚀

Moderate wear |

严重磨蚀

serious wear |

|

|

G15

|

0.45

|

0.4

|

0.3

|

0.2

|

|

G25~135

|

0.6

|

0.5

|

0.35

|

0.2

|

|

TYG2

|

0.55

|

0.5

|

0.35

|

0.25

|

|

TYG3~14

|

0.75

|

0.6

|

0.4

|

0.25

|

八、泵输送粘滞性介质所需功率倍数

|

粘度(mpa)

Viscosity(mpa) |

0~10000

|

10000~25000

|

25000~50000

|

50000~100000

|

100000~150000

|

150000以上

|

|

功率倍数

Multitude of power |

1.0

|

1.05

|

1.1

|

1.2

|

1.25

|

特殊设计

Special design |

九、轴封和泵部材料组合

|

轴

封 shaft seal |

|

||||

|

材

料 组 合 Material composition |

代号

codes |

转子

Rotors |

定子内衬

Liner for stators |

过流部件

Overcurrent parts |

|

|

M101

|

45

|

天然橡胶

Natual rubber |

45、HT200

|

||

|

M102

|

1Gr18Ni9Ti

|

天然橡胶

Natual rubber |

1Cr18Ni9Ti、ZG1CR18Ni9Ti

|

||

|

M103

|

45

|

丁腈橡胶

Paracril |

45、HT200

|

||

|

M104

|

1Gr18Ni9Ti

|

丁腈橡胶

Paracril |

1Cr18Ni9Ti、ZG1CR18Ni9Ti

|

||

|

M105

|

1Gr18Ni9Ti

|

食品橡胶

Food-oriented rubber |

1Cr18Ni9Ti、ZG1CR18Ni9Ti

|

||

|

M106

|

1Gr18Ni9Ti

|

氯磺化聚乙烯胶

sulfochlorinated polyethyene rubber |

1Cr18Ni9Ti、ZG1CR18Ni9Ti

|

||

|

M107

|

1Gr18Ni12Mo2Ti

|

氯磺化聚乙烯胶

sulfochlorinated polyethyiene rubber |

1Cr18Ni12Mo2Ti、ZG1CR18Ni12Mo2Ti

|

||

|

M108

|

45

|

乙丙橡胶

EPDM |

45、HT200

|

||

|

M109

|

1Gr18Ni9Ti

|

乙丙橡胶

EPDM |

1Cr18Ni9Ti、ZG1CR18Ni9Ti

|

||

|

M110

|

1Gr18Ni9Ti

|

氟橡胶

fLUORUBBER |

1Cr18Ni9Ti、ZG1CR18Ni9Ti

|

||

|

M111

|

1Gr18Ni12Mo2Ti

|

氟橡胶

Fluorubber |

1Cr18Ni12Mo2Ti、ZG1CR18Ni12Mo2Ti

|

||

| 注:食品橡胶不含对人体有害的添加剂 Note;The food-oriented rubber does not contain assitives detrimental to human health |

|||||

- 上一篇: 立式玻璃钢液下泵结构及安装尺寸

- 下一篇: ZW型无堵塞自吸排污泵安装示意图和安装尺寸图